Product List

Contact Us

Zhengzhou YiFan Machinery Co.,Ltd.

Address: The middle of zhengyuan road, xingyang eastern development zone, zhengzhou, PRC

Tel: +86-371-64966831

Fax: +86-371-64628872

E-mail: yifanec@yfmac.com

Yahoo: yifancrusher@yahoo.cn

Get Price and Support

Products

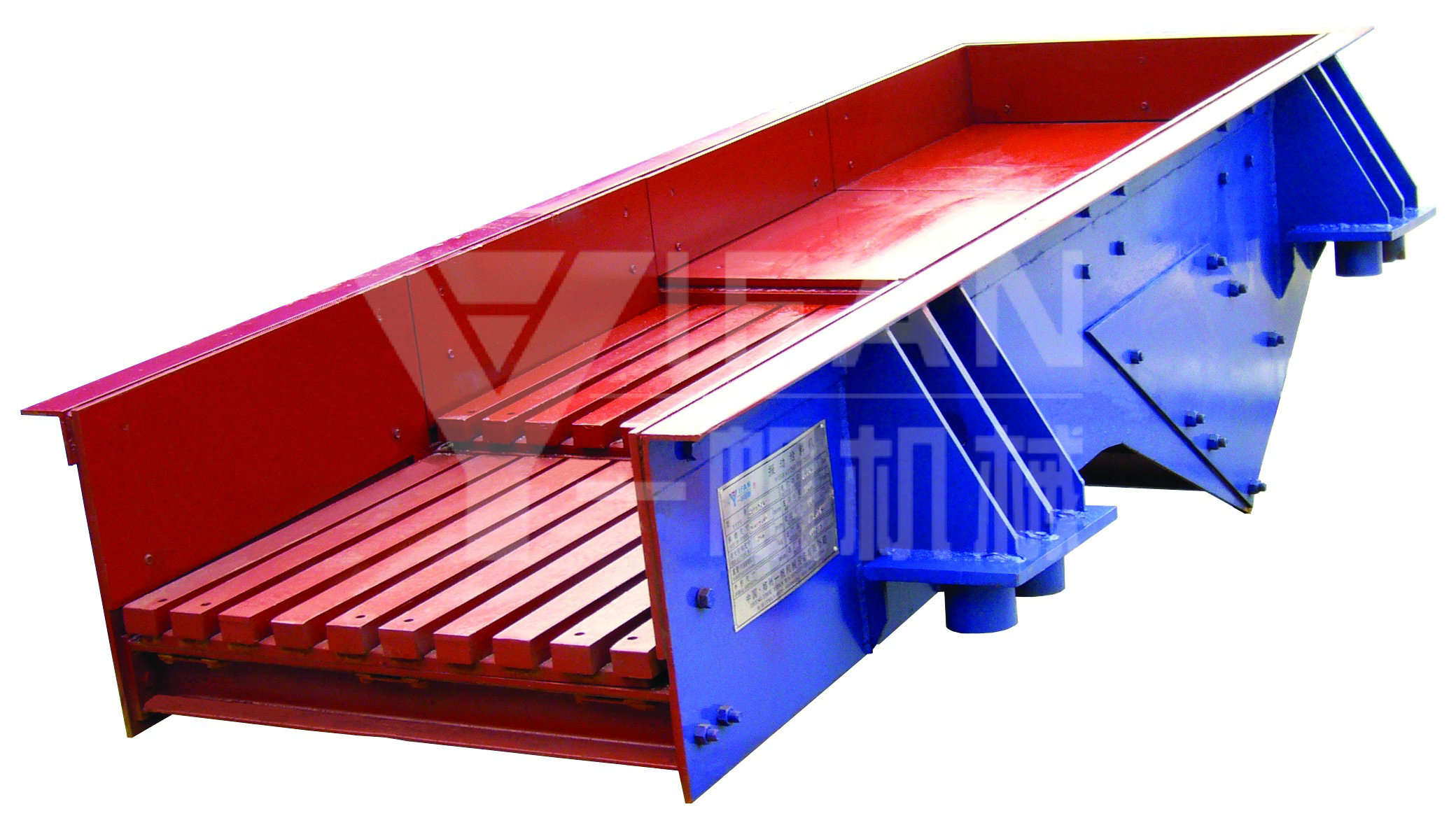

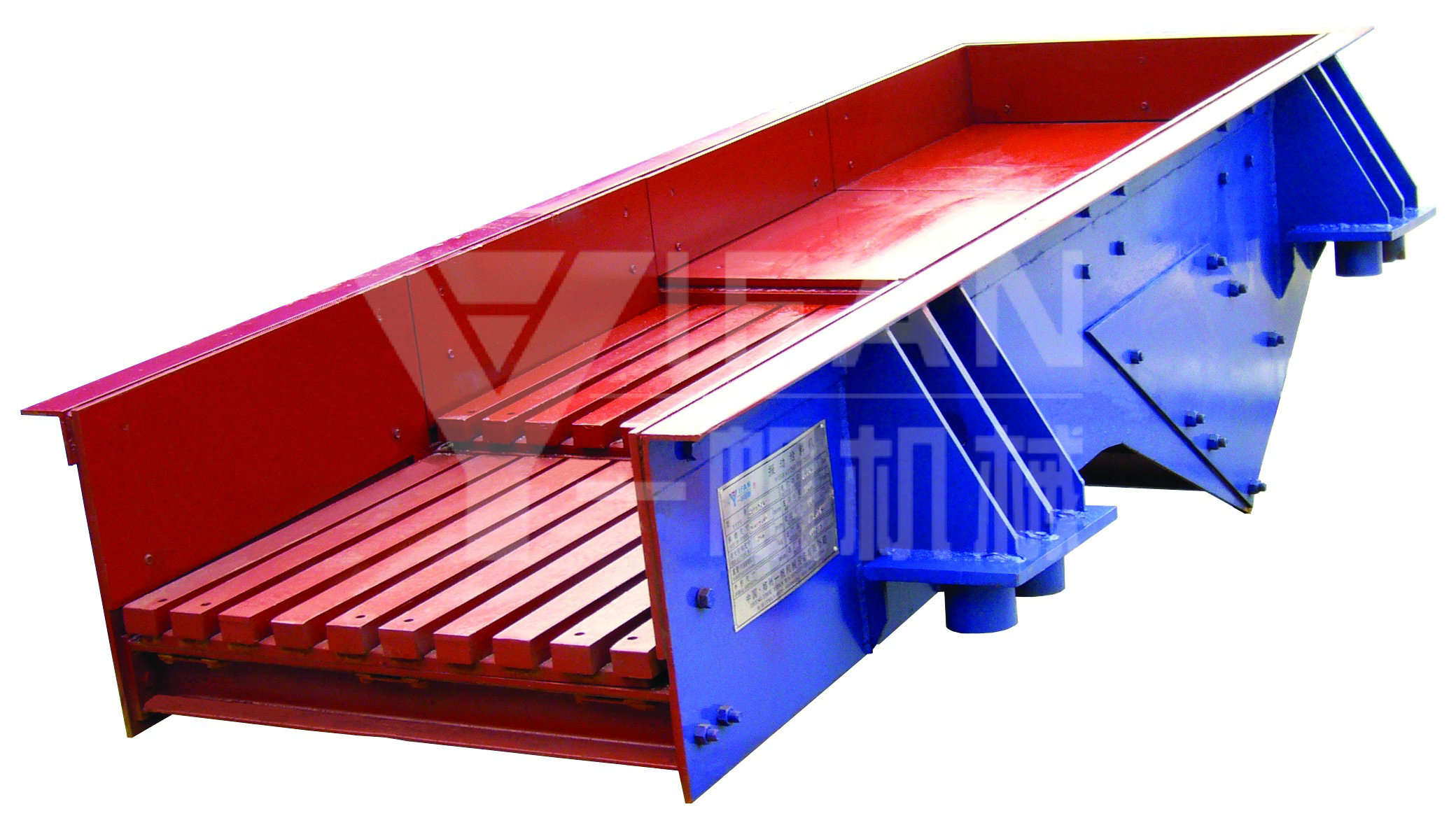

GZT Series Vibrating Feeder

GZT Series Feeder rod main technical parameters

GZT Series Vibrating Feeder rod Department of digestion and absorption of Sweden, Finland, design and manufacturing technology, and with the introduction of Japanese technology to produce vibration

motor as vibration source.

Feeder works:

GZT mainly consists of a series of vibrating feeder same parameters on the performance of the vibration motor excitation source, when the two vibrating angular velocity of the motor is the same for the reverse operation, the eccentric block of the inertial force generated in a specific phase of repetition stacking or offset. Resulting in huge synthetic excitation power, so that the body in the support for forced vibration spring, and as vibration-driven, driven to make the material in the chute slide and throwing motion, so that the material constantly move forward to achieve the purpose of feeding. When the material body through the slot on the sieve, the smaller material can fall through the sieve gap, without crushing process under the Road, played screening effect.

Scope:

Feeder in the production process, can the massive, granular materials from storage silos in uniform, regular, continuous feeding device to go into the subject in the sand and gravel production line, crushing machinery for continuous uniform feed material, and coarse screening material, widely used in metallurgy, coal, mineral processing, building materials, chemicals, abrasive and other industries crushing and screening equipment.

Features:

1 This series of product variety, and can be individually designed according to user requirements, specializes in manufacturing;

(2) All models feeder, can be easily implemented manually or automatically controlled feeding capacity;

3 smooth vibrating, reliable operation and long life;

4 exciting force can be adjusted, you can change and control flow, convenient adjustment and stability;

5 vibration motor as vibration source, low noise, low power consumption, the adjustment performance, no red material phenomena;

6 simple structure, reliable operation, easy installation, adjustment;

7 light weight, small size, easy maintenance, when the body is in a closed structure to prevent dust pollution

Technical parameters

GZT Series rod feeder main performance parameters:

GZT Series Vibrating Feeder rod Department of digestion and absorption of Sweden, Finland, design and manufacturing technology, and with the introduction of Japanese technology to produce vibration

motor as vibration source.

Feeder works:

GZT mainly consists of a series of vibrating feeder same parameters on the performance of the vibration motor excitation source, when the two vibrating angular velocity of the motor is the same for the reverse operation, the eccentric block of the inertial force generated in a specific phase of repetition stacking or offset. Resulting in huge synthetic excitation power, so that the body in the support for forced vibration spring, and as vibration-driven, driven to make the material in the chute slide and throwing motion, so that the material constantly move forward to achieve the purpose of feeding. When the material body through the slot on the sieve, the smaller material can fall through the sieve gap, without crushing process under the Road, played screening effect.

Scope:

Feeder in the production process, can the massive, granular materials from storage silos in uniform, regular, continuous feeding device to go into the subject in the sand and gravel production line, crushing machinery for continuous uniform feed material, and coarse screening material, widely used in metallurgy, coal, mineral processing, building materials, chemicals, abrasive and other industries crushing and screening equipment.

Features:

1 This series of product variety, and can be individually designed according to user requirements, specializes in manufacturing;

(2) All models feeder, can be easily implemented manually or automatically controlled feeding capacity;

3 smooth vibrating, reliable operation and long life;

4 exciting force can be adjusted, you can change and control flow, convenient adjustment and stability;

5 vibration motor as vibration source, low noise, low power consumption, the adjustment performance, no red material phenomena;

6 simple structure, reliable operation, easy installation, adjustment;

7 light weight, small size, easy maintenance, when the body is in a closed structure to prevent dust pollution

Technical parameters

GZT Series rod feeder main performance parameters:

| Model | Max feed size (mm) | processing capacity (t / h) | Motor Power (kw) | rod angle (°) |

Weight (kg) |

| GZT-0724 | 450 | 30-80 | 2×1.5 | 10 | 2422 |

| GZT-0932 | 560 | 80-150 | 2×2.2 | 10 | 2440 |

| GZT-0940 | 560 | 80-180 | 2×3.7 | 10 | 3700 |

| GZT-1148 | 600 | 150-300 | 2×5.5 | 10 | 4980 |

| GZT-1256 | 800 | 180-400 | 2×7.5 | 10 | 6760 |

| GZT-1256 | 1000 | 400-600 | 2×13 | 10 | 9180 |

Recommend News